Course Syllabus

It provides an overview of what you are going to learn.

- What is GD&T?

- Application of GD&T

- Measuring Instrument used in GD&T

- Machines used in GD&T

- Things to know in GD&T

- Objectives & subjective

- Dimensioning in GD&T

- What is Tolerance?

- Types of Tolerance

- Difference between Coordinate tolerance & Geometric Tolerance

- Application of tolerance

- Application of Tolerance in Manufacturing

- What is Datum?

- How Datum is Applied

- How to Apply Datum in Rectangular part

- How to Apply Datum in Cylindrical part

- Objectives & subjectives

- Positioning of Datum

- External & Internal Datum

- Multiple Datums in one component

- Datum Example

- What is Datum Target?

- Datum Target in Fix Elements

- Datum Target in Movable Elements

- Datum & Datum Target Requirement

- About Geometrical Tolerance

- Form Tolerance – Flatness

- Form Tolerance – Straightness

- Form Tolerance - Straightness - How to read?

- Form Tolerance – Cylindricity

- Form Tolerance – Circularity

- Form Tolerance - Circularity - How to read?

- Objectives & subjectives

- Orientation – Parallelism

- Orientation - Parallelism - How to read?

- Orientation – Perpendicularity

- Orientation - Perpendicularity - How to read?

- Orientation – Angularity

- Orientation - Angularity - How to read?

- Objectives & Subjectives

- Runout - Total Runout

- Runout - Total Runout - How to read?

- Runout - Circular Runout

- Runout - Circular Runout - How to read?

- Objectives & Subjectives

- Profile - Profile of Line

- Profile - Profile of Line - How to read?

- Profile - Profile of Surface

- Profile - Profile of Surface - How to read?

- Objectives & Subjectives

- Location – Concentricity

- Location – Symmetry

- Location – Position

- About Modifier

- Different Symbols in Modifier

- Modifier - Maximum Material Condition with Example

- Modifier - Least Material Condition with Example

- Modifier - Regardless of Feature Size

- Objectives & Subjectives

- Modifier - Tangency Plane

- Modifier – Independency

- Modifier – Translation

- Modifier - Projected Tolerance

- Objectives & Subjectives

- Modifier - Free State

- Modifier - Unequally Disposed

- Modifier - Continous Feature

- Modifier - Conical Taper

- Modifier - Slope Taper

- About Feature Control Frame

- About Virtual Condition

- About Resultant Condition

- Material Science and Engineering

- Manufacturing & Production

- Thermodynamics & Heat transfer

- Fluid mechanics

- Mechanical Design General Questions

- Quantitative Aptitude

- Autocad

- Solidworks

- GD&T

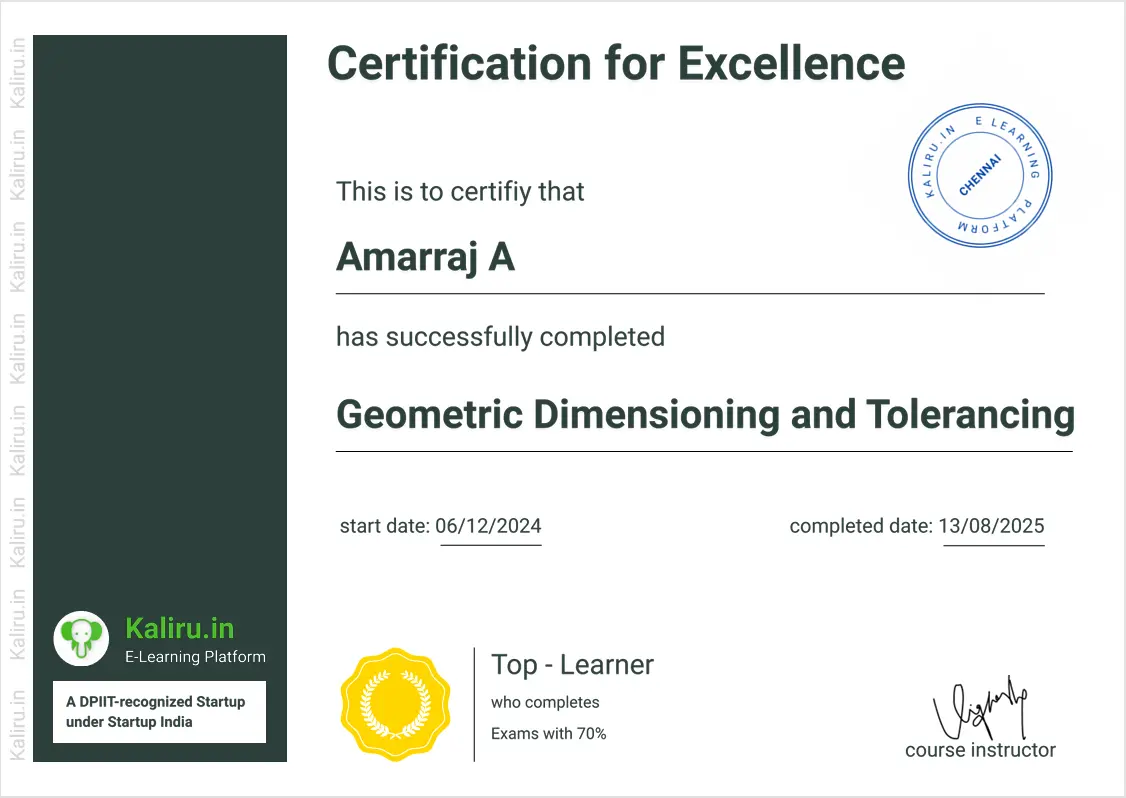

Enrollment Process

choose the access type you prefer to learn

Get a free e-book for lifetime access

The Ultimate interview guide

Aerospace, Automotive, Healthcare, Energy, HVAC, Manufacturing & Tooling, Metallurgical, Oil, gas & petroleum

Top Interview Questions & Answers

Material Science and Engineering, Manufacturing & Production,Thermodynamics & Heat transfer, Mechanical Design, Quantitative Aptitude

Frequently asked questions

Here are some common questions about our company.

Every industry uses GD&T tolerance to convey design knowledge to manufacturing based on component fixing, machining, and inspections so that engineers can grasp it simply.

All industries employ GD&T, but the manufacturing sector is particularly affected. This implies that if you design or manufacture a component, it will be assembled into another part, therefore you need to be aware of where to make repairs because we don't receive the real product from design to manufacturing.

If you don't have enough cash to buy our course, you can pay in two installments.

Where skills meet excellence

Where skills meet excellence