VEERA VIGNESH BALA N

Mechanical Design Engineer

veeravignesh969@gmail.com

Bachelor of Mechanical Engineering

Peri Institute Of Technology, Chennai, Tamil Nadu, India

Language: English, Tamil

Experience:

Graduate Engineer Trainee

Tamilnadu State Transport Corporation. (JAN-2018 to JAN2019) Pollachi Coimbatore, Tamil Nadu, India Assisted in vehicle maintenance planning and operational efficiency improvement & Gained practical skills and Problem solving Skill

Qc Line Inspector

Sandfits foundries private limited (Mar-2021 to Feb2023) ,Coimbatore, Tamil Nadu, India. Monitoring Operations to ensure that they meet Production Standards According to Drawings.

Utilized dimensional measuring tools (calipers, micrometers) and visual inspection techniques to identify surface and structural defects.

Ensured proper calibration and maintenance of all inspection tools, enhancing Measurement accuracy

Design Engineer

Bhagavathi Precision Products O

3D modelling E-vehicles Sheet metal fabrications GD & T Area of Interest Languages Known (FEB -2023 to Mar-2024) Coimbatore ,Tamilnadu,India.

Utilize Solid works software and peripherals to develop new conceptual design for fabrication and manufacturing.

Reverse engineering to prepare AutoCAD drawings. Convert AutoCAD drawings and hand sketches in to solid works 3D Models and rendering it to visualize.

Develop and Prepare Detailed Tool design for sheet metal Parts& Prepare Laser drawings for laser and bending Operations.

Prepare bill of materials and prepare 2d drawings for sheet metal works.

Design Engineer

Indofen Furnaces LLP,Coimbatore (MAR 2024-DEC 2024),Coimbatore Tamilnadu. Creating structural Model Fabrication Furnaces For Customer needs.

Preparing detailed Fabrication,Sheetmetal,Assembly,Nesting,BOM generation in modeling software and Excel

3D Modeling Intern

LAYERS 3D Printing & Modelling,Abu Dhabi-UAE (JAN 2024-Precent), Abu Dhabi-UAE.

Designed and developed 3D models and assemblies using SolidWorks, Ensuring compliance with technical specifications and design requirements.

Prepare Stl. files for creating 3d Prototype.

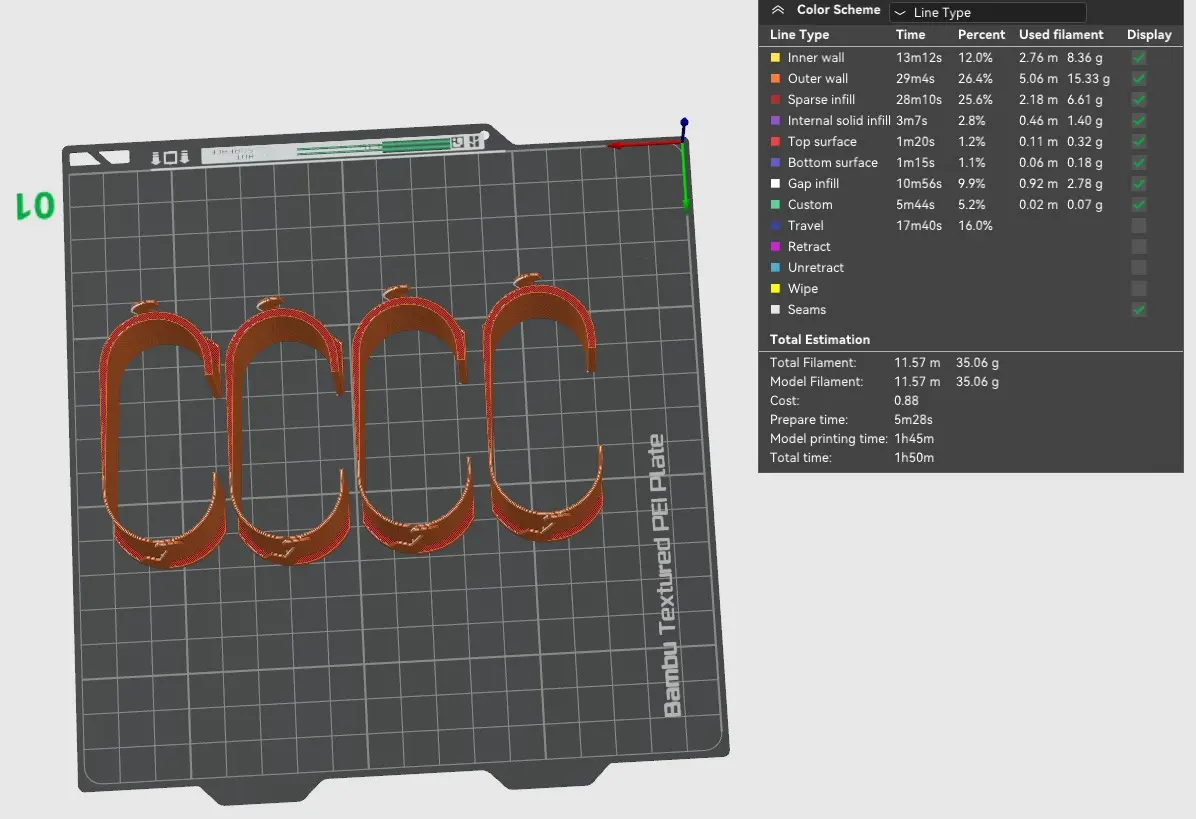

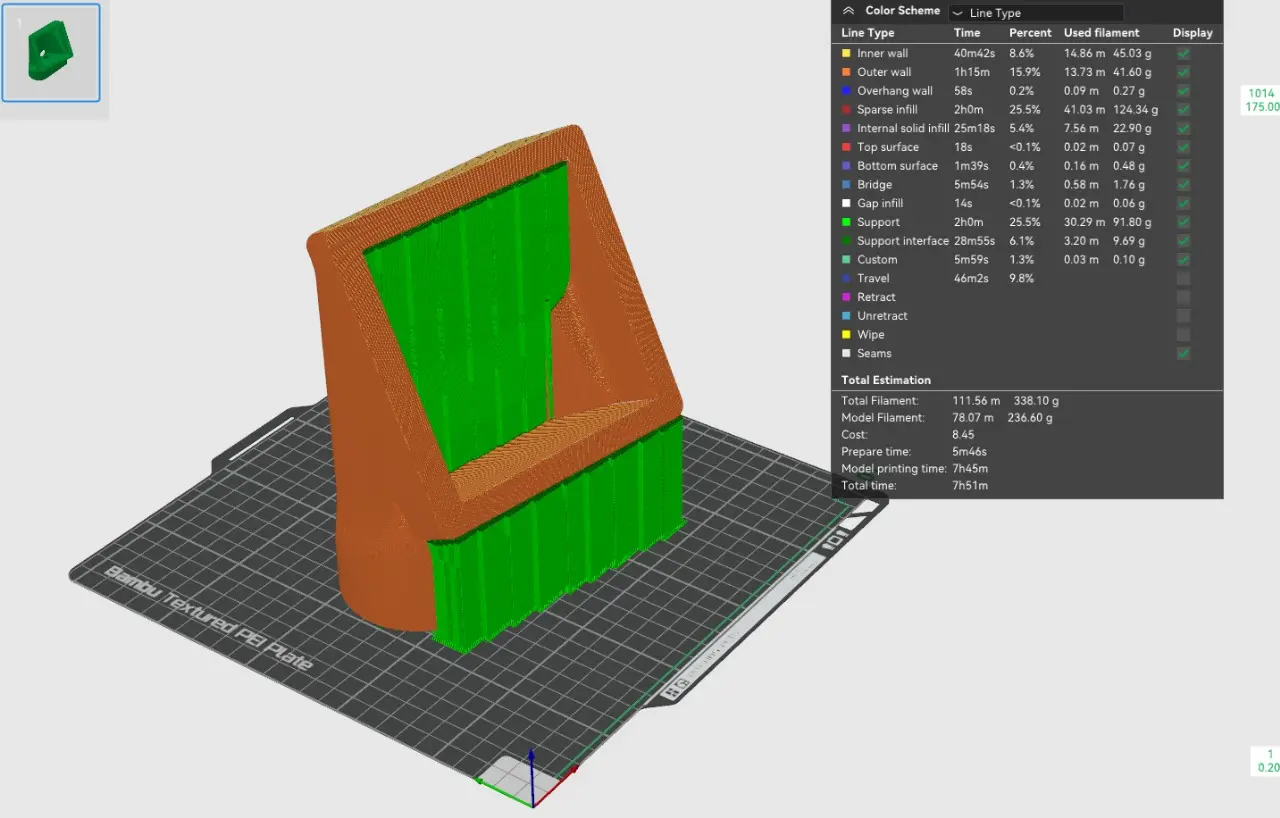

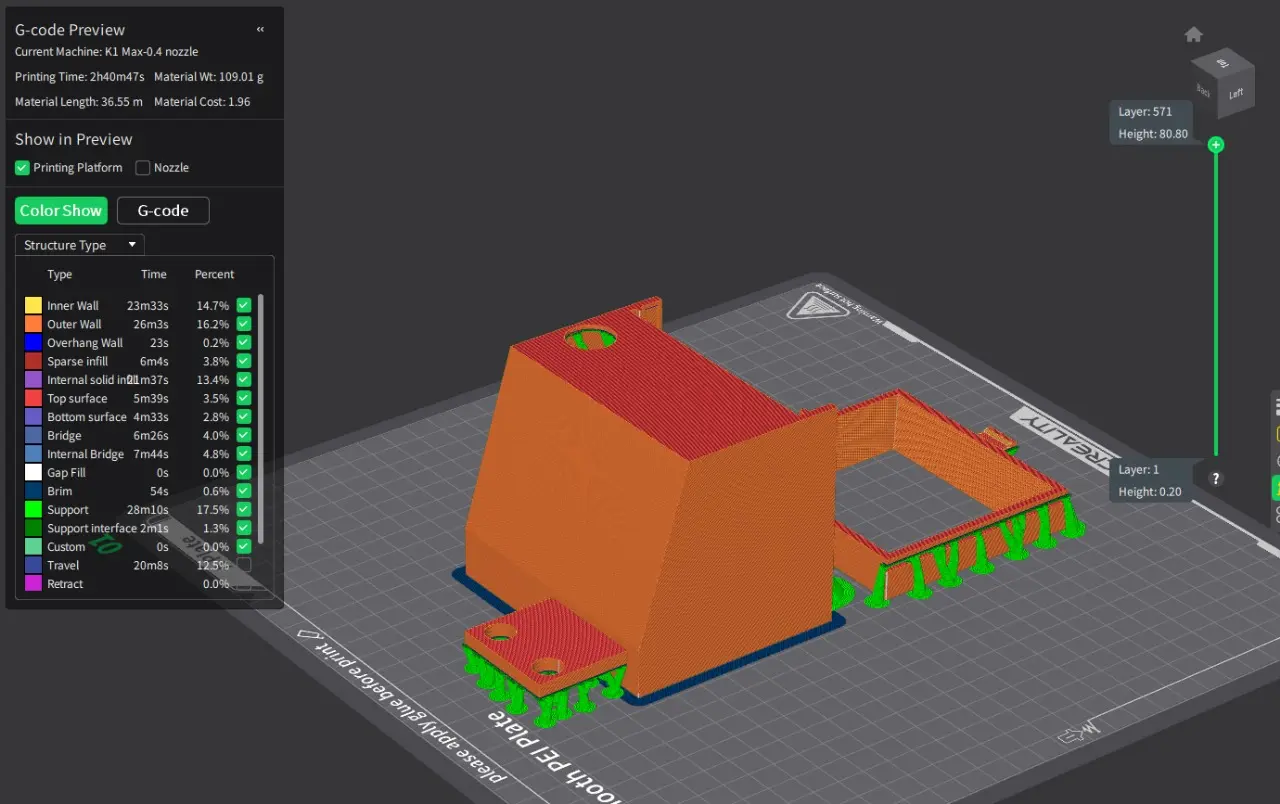

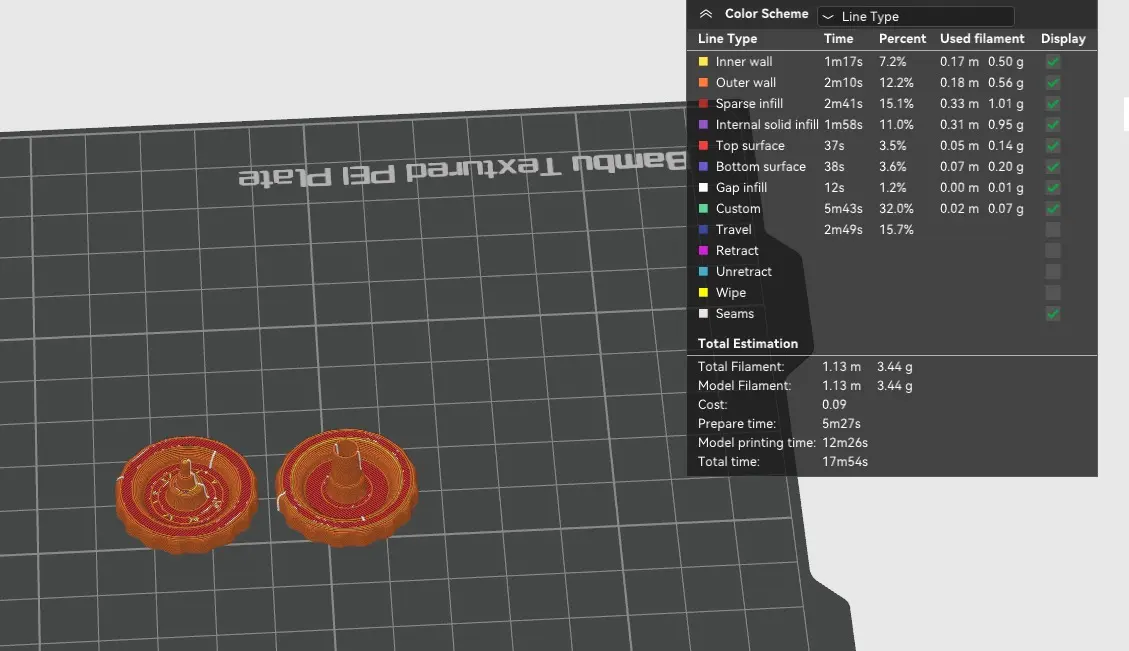

Prepared 3D models for 3D printing using slicing software like Ultimaker Cura, Creality, and Bambu-labs. Conducted design iterations to improve product functionality, Reducing production time by reducing support to Model.

Design Skills:

These skills include the ability to use software tools for designing detailed 3D models of physical objects

AutoCAD

Ability to create and comprehend 2D drawings using tools such as command tools, annotations, orthographic projection, and industry-based structured designs.

Solidworks

Proficient in SolidWorks for 3D modeling, including part design, assemblies, and complex surface modeling. Skilled in creating technical drawings and applying GD&T for precise manufacturing

Creo

It is a parametric CAD software that supports both solid and surface modeling. It integrates various design and simulation tools into a single platform

Make a Donation

3D Modeling

Sheetmetal Fabrications

E-Vehicles

GD&T

3D Printing Models

Applications: Used in robotics, automotive components, or customized fixtures

Key Features: Symmetrical geometry for balance and uniform stress distribution, Overhangs optimized for minimal support usage, Structural reinforcements for durability

Material used: PLA/ABS/PETG

Certification

SOLIDWORKS PROFESSIONAL

Using parametric characteristics to model components in 3D Product design encourages creative thinking, allowing for the development of unique solutions and features. allows complicated shapes to be created using forming, punching, cutting, and bending techniques, Modelling assembly with various mates, assessing tools, and draughting with comments and projections